Focus Project with Pressure Vacuum Relief Valves

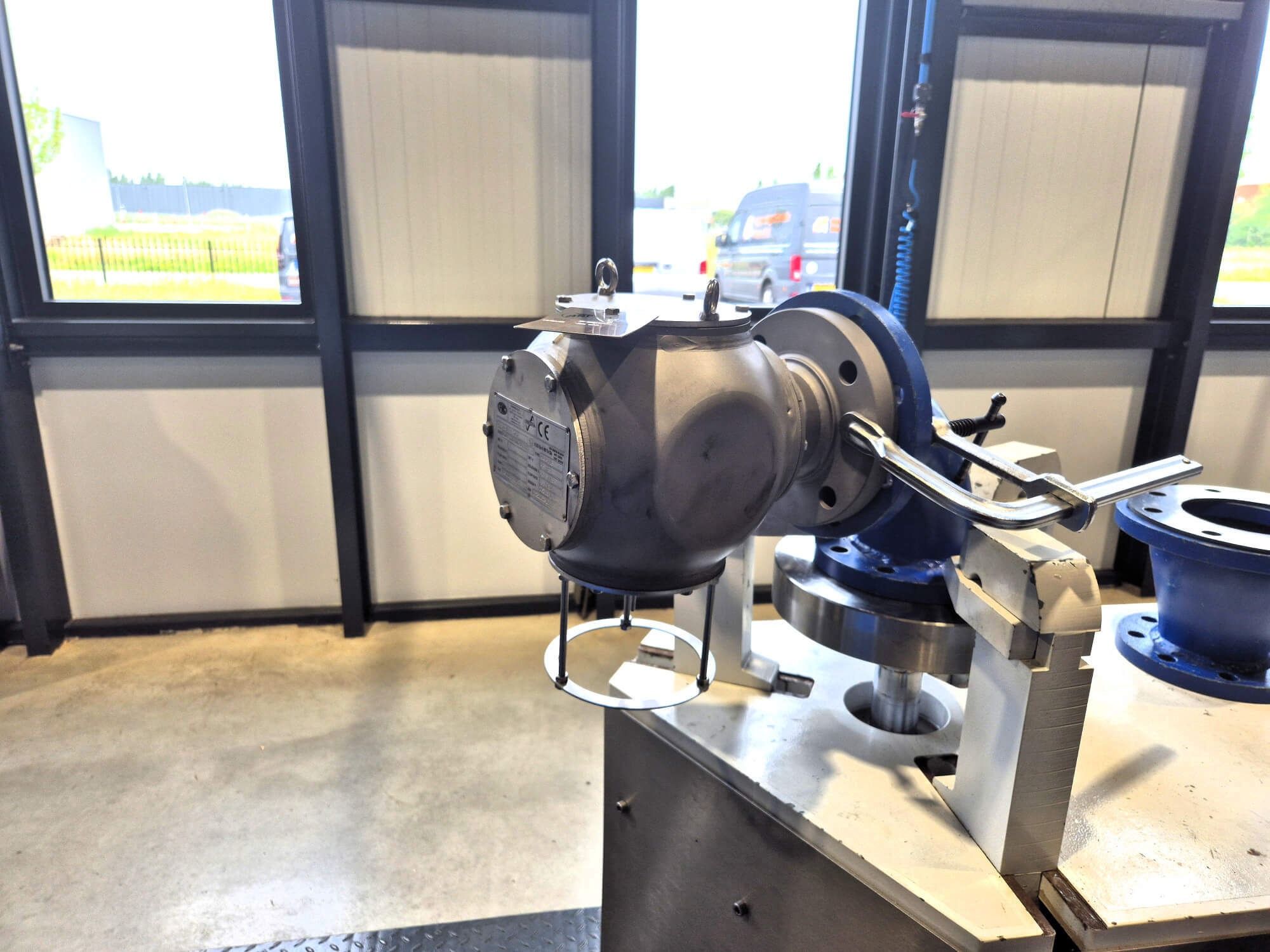

PPS International supplied a set of Vacuum Valve Modular DN80/3” units to a leading global manufacturer of advanced plastics, based in the Netherlands. Designed and manufactured in Italy by a specialist in high-performance valve technology, the valves were delivered fully assembled and factory-tested according to the required specifications. Each unit is constructed from AISI 316 / 316L stainless steel materials, featuring PTFE diaphragms and spring-loaded pallets for optimal vacuum performance. Upon arrival, all documentation, including GA drawings, internal test reports, and 3.1 material certificate, was verified before moving on to the next stage of quality assurance.

Retesting for transport integrity

Before proceeding to surface treatment, each valve underwent a retesting procedure to ensure that the internal settings and performance had not been affected during transport. This additional verification step was part of our quality assurance process, confirming that the valves maintain their original vacuum side setting of -25 mbarg and flow capacity of approximately 465 Nm³/h at 10% overvacuum.

Painting and surface finishing

After arrival, the valves were transferred to Appendage Revisie Peene (ARP) for both retesting and surface finishing. As one of our trusted partners, ARP is well known for their precision and expertise in valve refurbishment, testing, and coating. Each valve was carefully retested to verify that transport had not affected its internal settings or vacuum performance, ensuring compliance with the specified -25 mbarg setting. Following successful verification, the units were professionally prepared, masked, and painted in ARP’s controlled paint booth, achieving a durable and corrosion-resistant finish that meets the highest quality standards.

Ready for delivery

Once painted, the valves received new tag plates and final identification checks before being packed for transport to the production site. The finished units represent the combined quality efforts of multiple partners, high-end Italian manufacturing, Dutch precision retesting and finishing, and our coordination throughout the process to deliver equipment ready for seamless installation and operation.

Interested in our services?

Get in touch!

Make an inquiry and we'll assist as soon as possible.

Mark Tempelaar

Sales Manager