Focus Project with Actuated Butterfly Valves

PPS is proud to have successfully delivered Actuated Butterfly Valves for a Vacuum Emission Reduction System for one of our clients. This project was particularly significant, as we handled it from start to finish, including an advisory role during the engineering phase. It was a true collaboration, with open communication and close cooperation between our team, the client, and our suppliers. Despite the challenges posed by tight deadlines and extensive engineering work, we managed to deliver the project on time, helping our client meet their key deadlines.

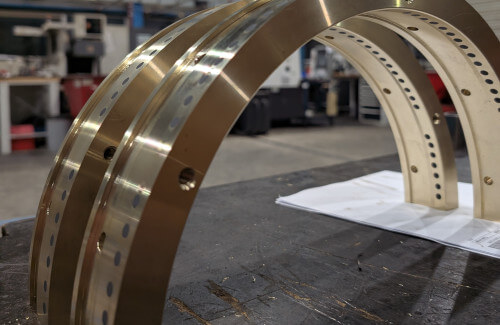

Design & Engineering

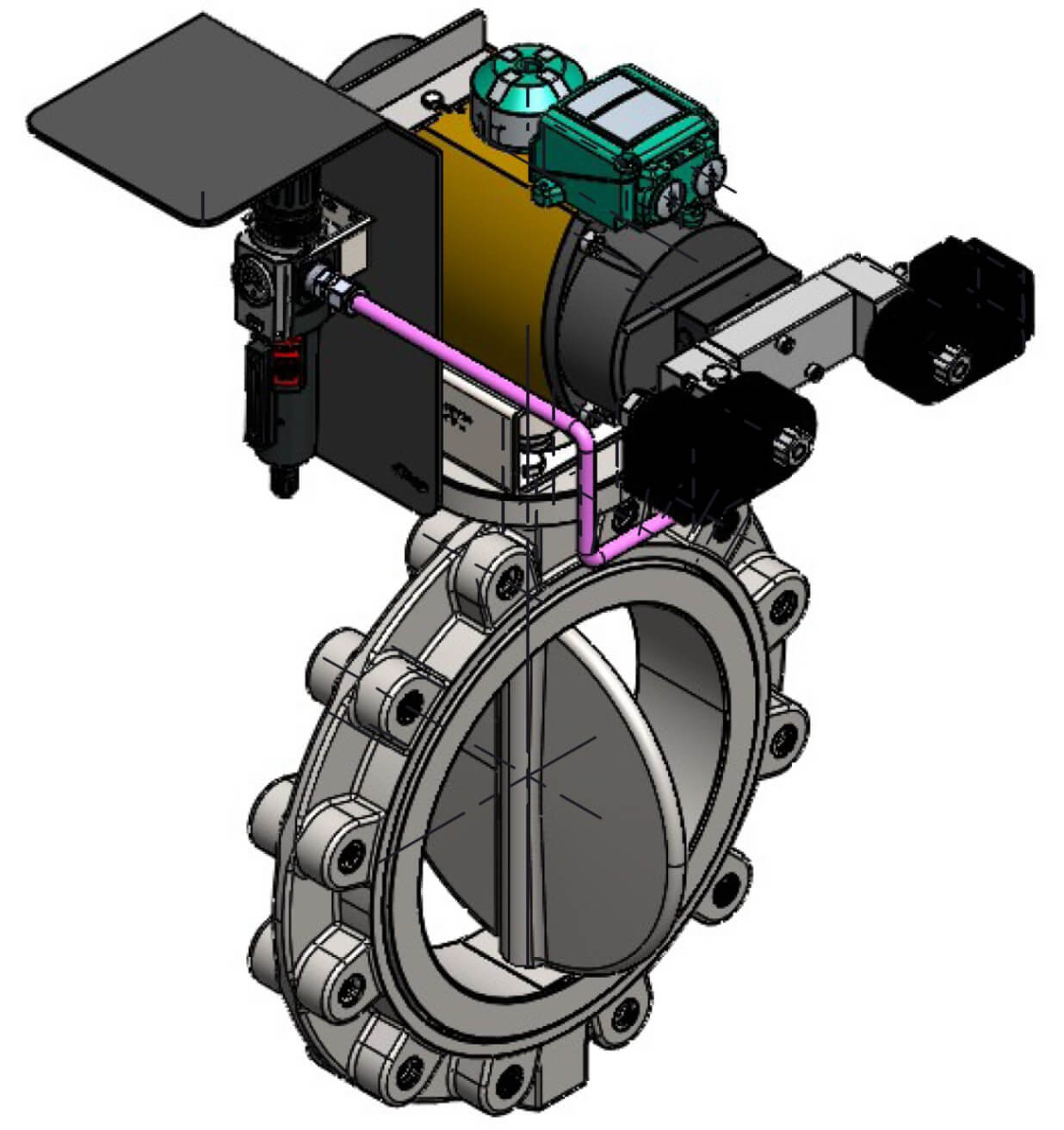

The design for these Actuated Butterfly Valves was based on the client’s medium and the need for a long-lasting solution. Together with the valve manufacturer, we advised a VITON seat for the valves, which is also bonded to the body to ensure durability and long service life. One of the unique challenges of this project was designing for an unusually slow opening and closing time of 30 seconds.

Additionally, these on-off valves were supplied with a comprehensive databook, which included the following key documents:

-

Material and test certificates to EN 10204 3.1, including hydrostatic and seat leakage tests

-

Certificate of Conformity for the assembly

-

Dimensional drawings for the assembly

-

Actuator sizing information

-

Manufacturer Declaration of Conformity

-

Installation, Operating, and Maintenance Manuals (IOM)

-

Hazardous Area Test Certificates

Procurement of Valves, Actuators, and Accessories

The procurement phase involved sourcing high-quality valves and actuators from trusted suppliers. We procured the valves from TTV Valves in Spain, while the NORBRO actuators came from Flowserve in the Netherlands. Several accessories were included on the actuators, such as:

-

Herion 5/3 solenoid valve

-

Herion NAMUR throttle control plate

-

Pepperl & Fuchs inductive switch (top-mounted on the actuator)

-

Pepperl & Fuchs puck

-

Norgren Filter Regulator

Although there were some supply chain challenges, these were on time resolved without causing any delays to the project. Thanks to our project management system and milestone tracking tool, we were able to ensure that every part of the project was designed, confirmed, and delivered on time, allowing for a smooth progression toward assembly.

Assembly and Testing, Including Client Witness for Final Approval

The assembly and testing phase took place at Flowserve's facility in the Netherlands. We conducted a thorough Factory Acceptance Test (FAT) to ensure everything functioned as expected, including the essential time test for the slow operation. The client was closely involved in this phase, sending two specialized engineers to witness the FAT and provide final approval. This collaborative approach allowed us to ensure that the client was fully satisfied with the performance and quality of the system before moving forward.

Final inspection & Packing

The final inspection was carried out in our warehouse, where we carefully checked the installation of the actuators, ensuring they were properly fitted and in accordance with the provided drawings. We added tag plates with PPS company details to each component, ensuring full traceability. The packing process was also handled with the utmost care by our warehouse team, ensuring that all components, including accessories, were securely packed to avoid any damage during transport.

For shipping, we used our standard forwarder, who is experienced in handling PPS orders.

Need Help with Similar Projects? Get in Touch with Us!

If you’re planning a similar project, our team of specialists is ready to help. With years of experience and strong partnerships with industry-leading suppliers, we are confident in our ability to deliver high-quality, reliable solutions tailored to your needs. Whether it’s design, engineering, procurement, or assembly, we are here to assist you every step of the way.

Feel free to reach out to us by email or phone, and we’ll be happy to discuss your project details and provide open, honest advice.

Interested in our services?

Get in touch!

Make an inquiry and we'll assist as soon as possible.

Mark Tempelaar

Sales Manager