PPS Workshop Highlights

At PPS, we’re proud to give you a look inside our workshop. From assembling actuators onto valves to function testing with precise opening and closing times tailored to client specifications. The valves from this order may be small, but they’re just as important as any of the big ones. One of the recent projects involved the full assembly of two compact yet high-performance ball valve units for a client in the specialty chemicals sector. Each unit features a ½" Mars Series 83 three-piece heavy-duty ball valve, built to handle demanding process conditions with a fire-safe design, RPTFE seats, and full compliance with NACE MR-0175. The valves were equipped with Actreg ASR0020 spring-return actuators and IFM MVQ101 position sensors for accurate open/close indication.

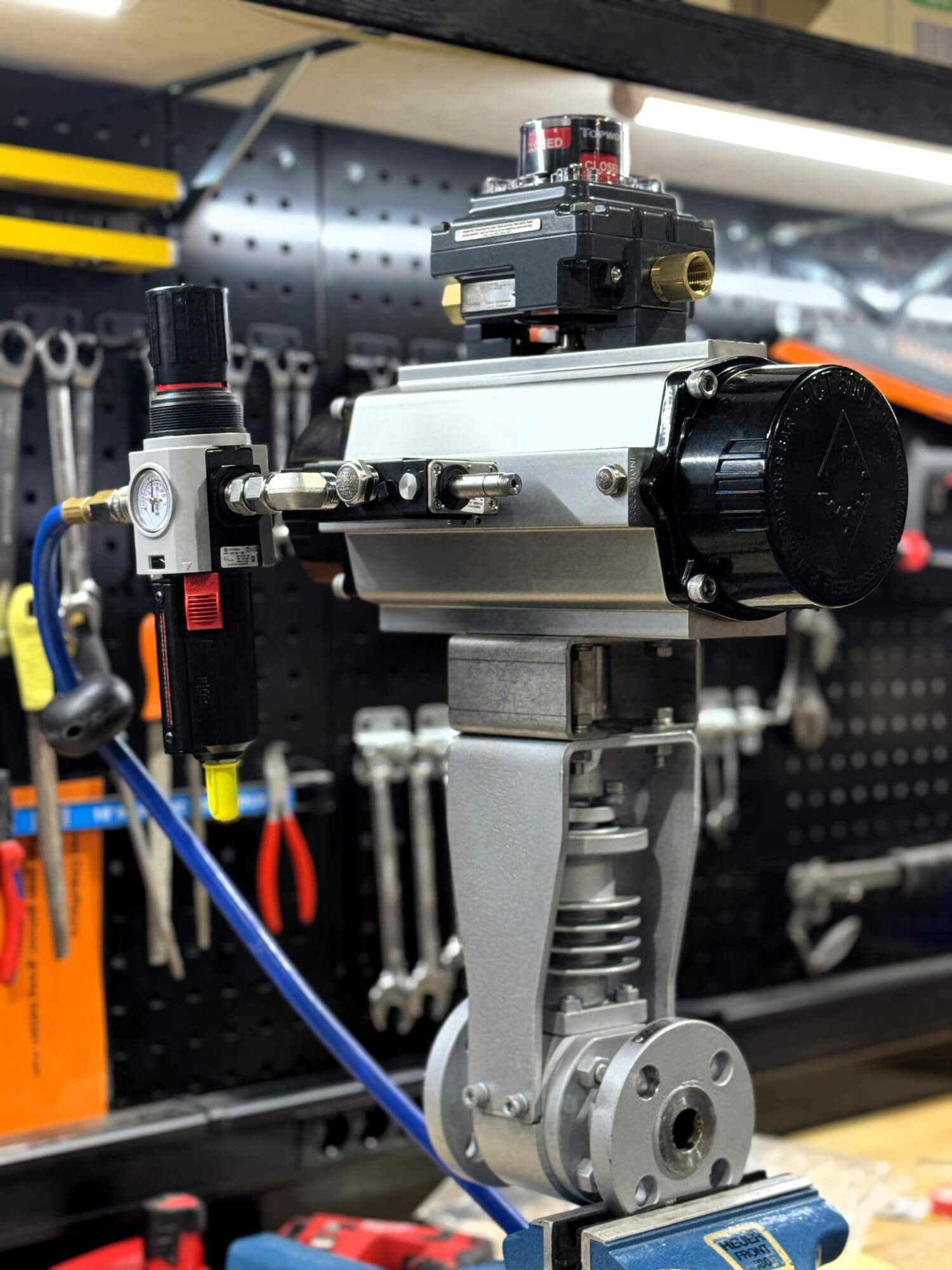

This second project involved the complete assembly of a robust, high-temperature ball valve automation package. The 1” Class 300 full bore valve was built for demanding conditions, with a forged F22 body, CCr-coated internals, and graphite packing designed to handle temperatures up to 550°C and pressures up to 50 bar.

At our PPS workshop, the valve was equipped with a spring-return Actreg ASR500 pneumatic actuator, along with a Topworx TXP switchbox, Herion solenoid valve, and Norgren air set. After final assembly, the unit was function tested to ensure fast closing performance, in line with the project requirements. A demanding spec, but one we’re very familiar with. This type of high-temperature assembly has become standard practice for both the client and our team.

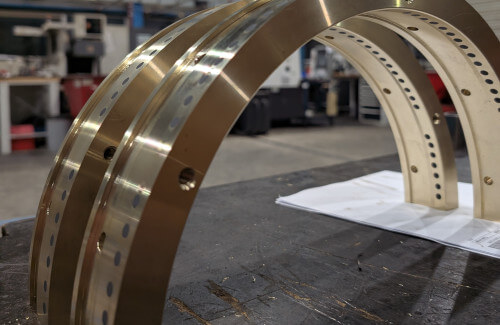

Our last workshop project in this news item involved the assembly of a DN150 stainless steel ball valve with a spring-return actuator package. The valve features a full bore design with RF flanges, modified PTFE seats, and is rated for pressures up to PN16 and temperatures ranging from -50°C to 200°C.

To automate the valve, we fitted an Actreg ASR1200 spring-return actuator along with a Festo 5/2 & 3/2 NAMUR solenoid valve. Given the size and especially the weight of the components, safe handling during assembly was essential. That’s why our team used the Ventil SteadyStand. This is a practical support tool for large valve assemblies, helping to ensure stability and protect both the equipment and our technicians during the process.

Interested in our services?

Get in touch!

Make an inquiry and we'll assist as soon as possible.

Mark Tempelaar

Sales Manager