Avoid Extra Charges with These Stackable Shipment Tips

Efficient space utilization in logistics is essential to keep shipping costs down, as unused space leads to unnecessary charges. When shipments are non-stackable, couriers may apply additional fees due to the wasted space and higher handling costs. To avoid these extra charges, it's important to clearly label non-stackable shipments and use cones around the packages. On the other hand, stackable shipments should meet the required criteria to ensure they are properly arranged, preventing any potential surcharges. By following these simple guidelines, you can help optimize logistics processes and reduce additional costs.

Stackable and Non-Stackable Pallets

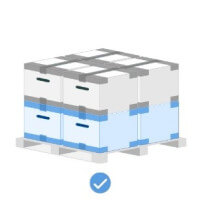

Stack Evenly for Strength

Even stacking distributes weight evenly, ensuring stability and reducing the risk of damage. It keeps your shipment secure during transit and protects against shifting or collapsing.

Avoid Uneven Stacking

Uneven stacks weaken stability, leading to potential tipping, damage, and extra handling costs. Proper stacking ensures safety and prevents costly issues.

Keep Items Within the Pallet Edge

Packing items squarely within the pallet prevents overhang, ensuring stability and protecting goods from damage during transit or handling.

Avoid Overhang Risks

Overhanging items are prone to breakage, instability, and handling issues. Proper alignment ensures safety and reduces the risk of costly mishaps.

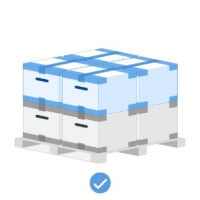

Create a Flat, Level Top

A flat, level top ensures stability and allows safe stacking, preventing packages from shifting or toppling during transit.

Avoid Uneven Surfaces

Uneven tops weaken the stack and risk collapse, leading to damage and extra handling costs. A strong, level surface ensures secure shipping.

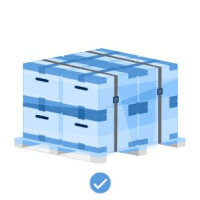

Secure with Strapping and Wrapping

Strapping and stretch wrapping keep items firmly in place, preventing movement during transit. Wrapping the pallet and items together adds extra stability.

Avoid Loose Packing

Without proper wrapping, items can shift, fall, or get damaged. Securing everything tightly ensures safe handling and reduces the risk of mishaps.

Protect Sharp Items with Padding

Wrap sharp items in protective padding to prevent damage and ensure safe handling. Make sure all edges are covered and secure.

Avoid Protruding Edges

Exposed edges can cause injuries, tear wrapping, or damage other shipments. Proper padding and coverage keep your shipment safe and compliant.

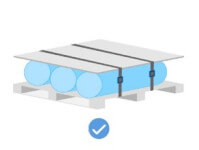

Properly Secure Tubes for Safe Shipping

Heavy tubes must be strapped securely to a pallet to ensure stability, following stacking and wrapping guidelines. Light tubes are best packed in triangular shipping tubes to prevent rolling and damage during transit.

Use a Clear "DO NOT STACK" Label

For non-stackable parcels or pallets, prominently display a "DO NOT STACK" label to ensure proper handling. This helps prevent stacking that could damage your shipment and ensures it is treated according to its specific requirements.

Use a Cone for Non-Stackable Items

Place a cone on top of non-stackable parcels or pallets to clearly indicate that stacking is prohibited. This visual cue helps prevent improper stacking and ensures your shipment is handled safely and in accordance with its needs.

We’re Here to Help with Packaging Solutions

Clients and suppliers are always welcome to discuss the best packaging options for their orders to ensure everyone is aligned and agrees on the terms of shipment. We are committed to providing advice and guidance on packaging, ensuring the products are shipped safely and efficiently. Don’t hesitate to reach out if you need assistance with any packaging questions or concerns.